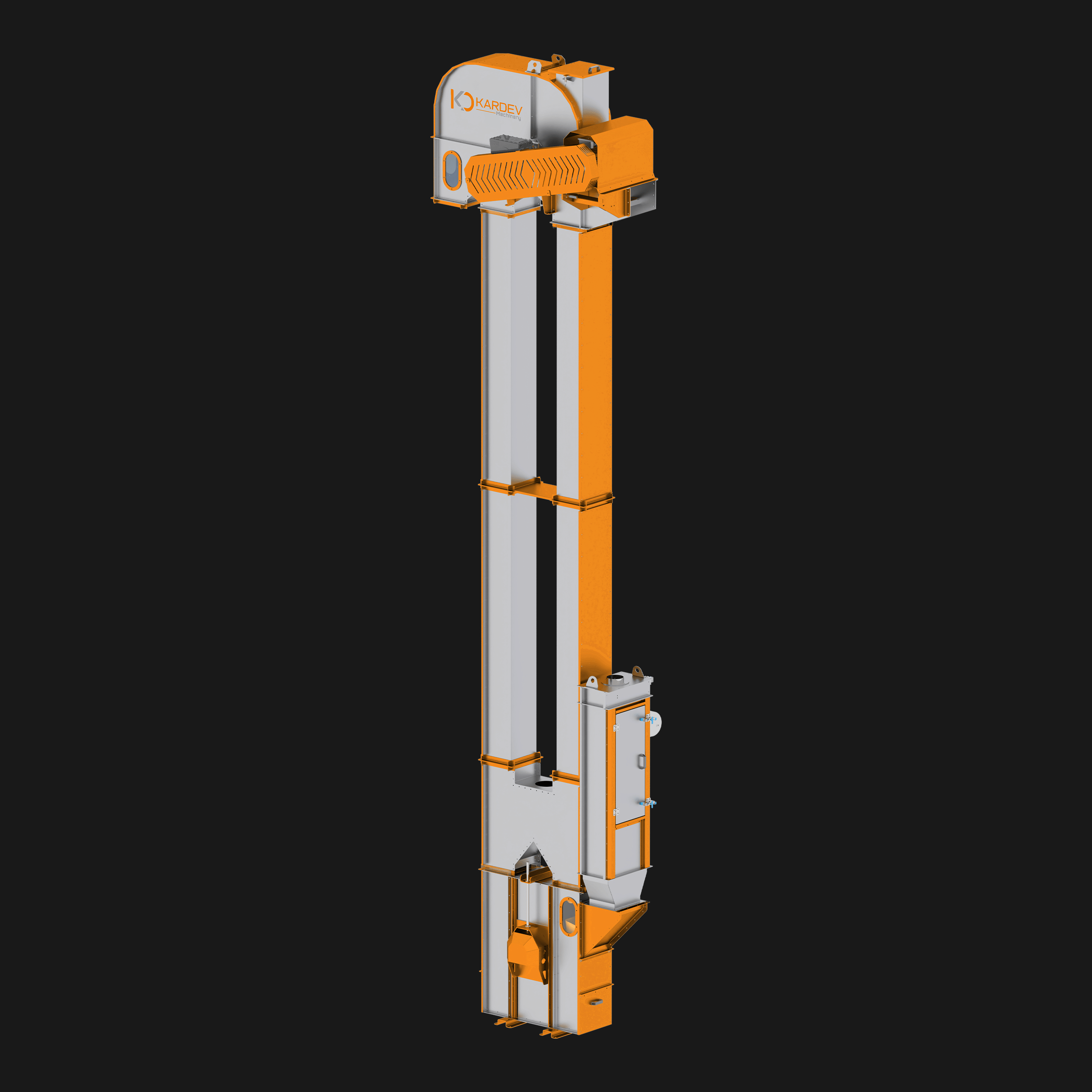

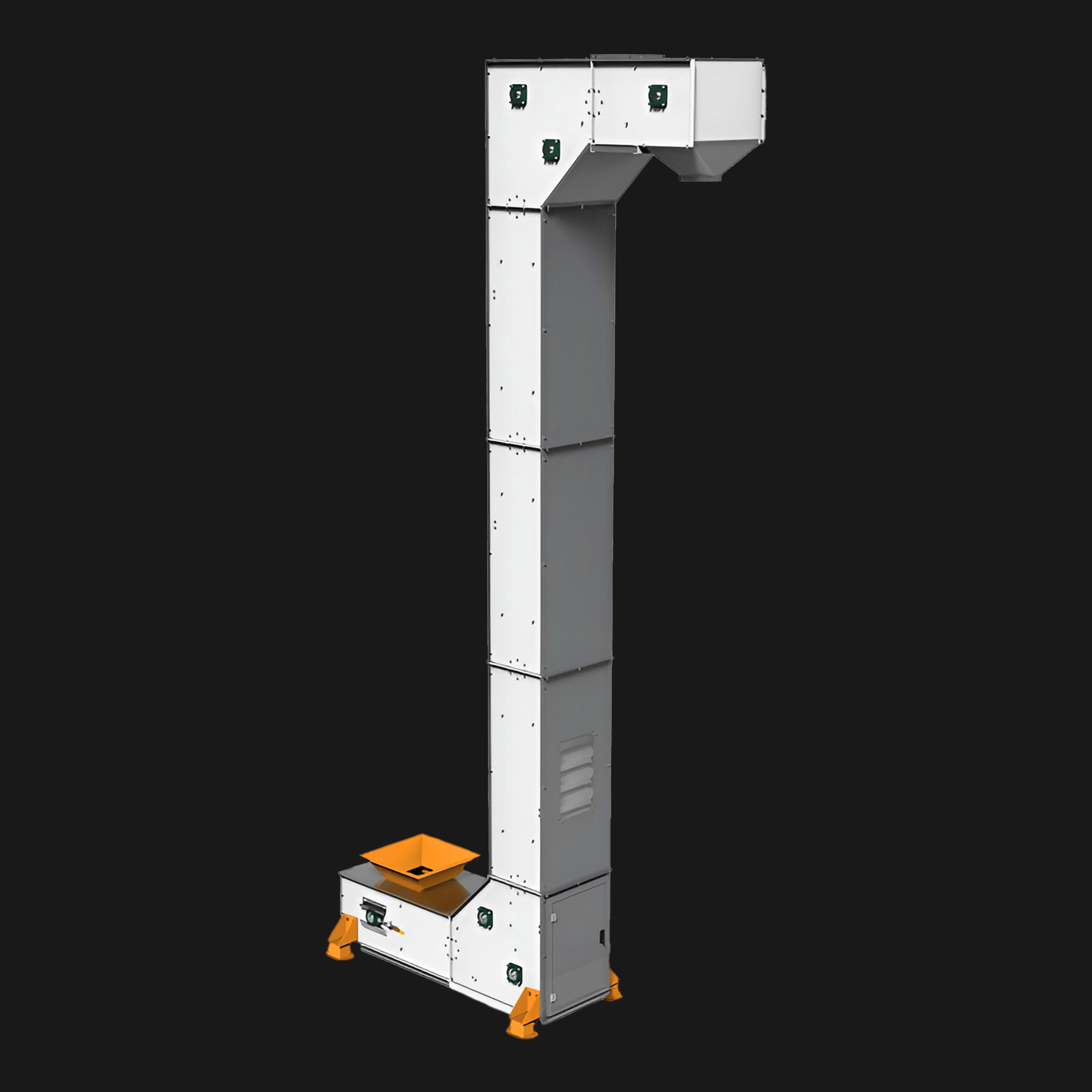

Bucket Elevator

Bucket elevator; It is the carrier that ensures the vertical transmission of raw materials and products in feed, food, chemical and fertilizer plants. It carries out the transportation with buckets attached on a belt that makes ring movement.

Depending on the propeller engine’s power, a direct coupled engine, reduction engine or a strap-rim propelled reduction engine can be used for safest and efficient drive. The return-lock on the reductors prevent buckles from rolling back and spilling material in case of power outages. Rubber plated propelling barrel can be serviced easily via conoid pliers.

There is a stretching mechanism to determine the strap’s tightness and centrifuge. The idler barrel is designed with gratings in order to clean between the strap and the idler barrel. Cycling sensor which records/enumerates the idler barrel’s number of rotations provides a safe operation. Optionally two sensors which monitor strap slipping can be attached opposite to each other.

Features:

- Cord fabric tape suitable for capacity is used.

- Buckets are connected to the belt by bolts.

- There is a filter cloth in the lower pipe and upper head to expel the air trapped inside.

- Pipes are bolted to each other and have flange connection.

- Buckets are plastic and have high flexibility and long service life.

- The lower drum is specially designed to prevent belt slippage.

- It can be manufactured from galvanized or stainless materials.

- Product inlets and outlets can be made with Hardox or Tivar coating.