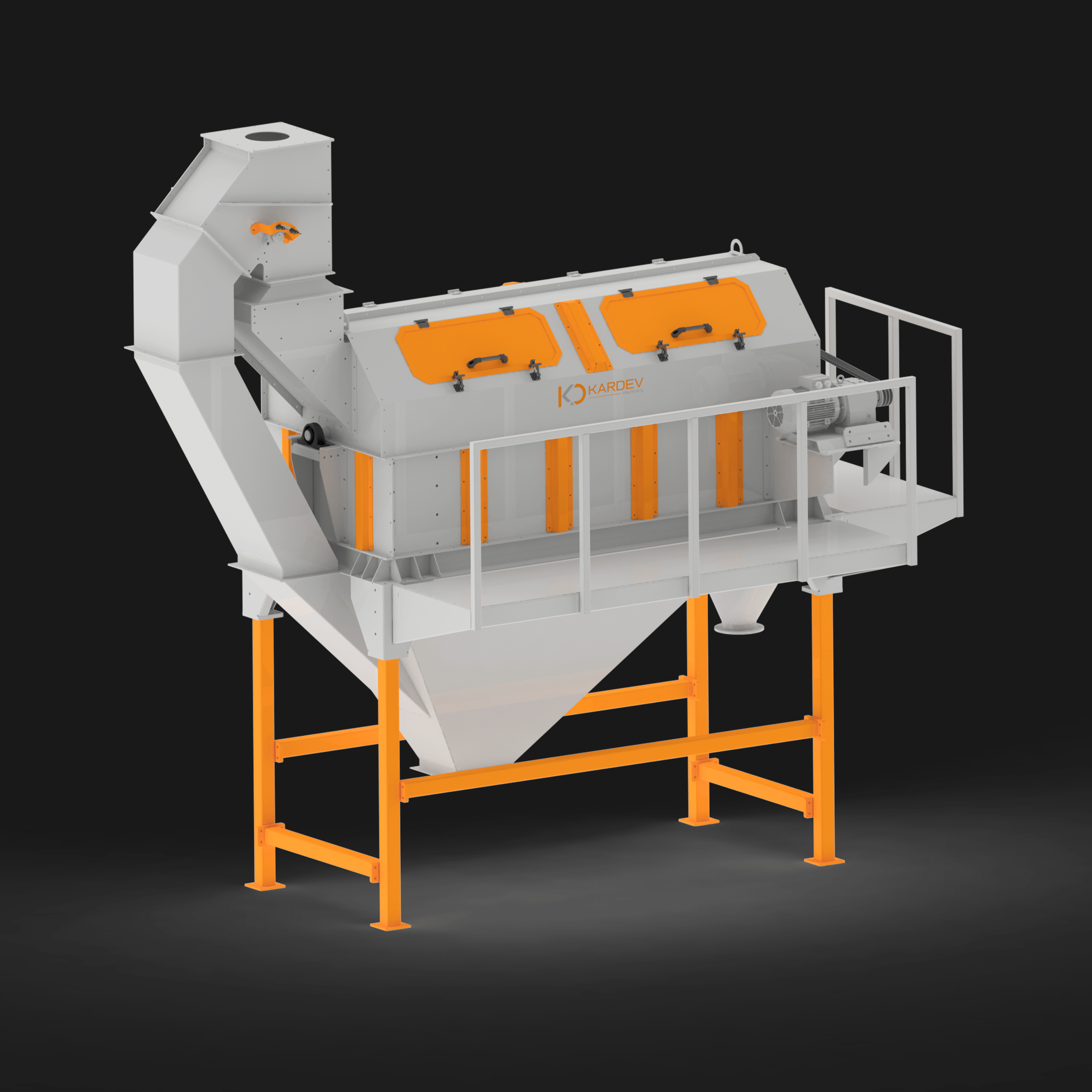

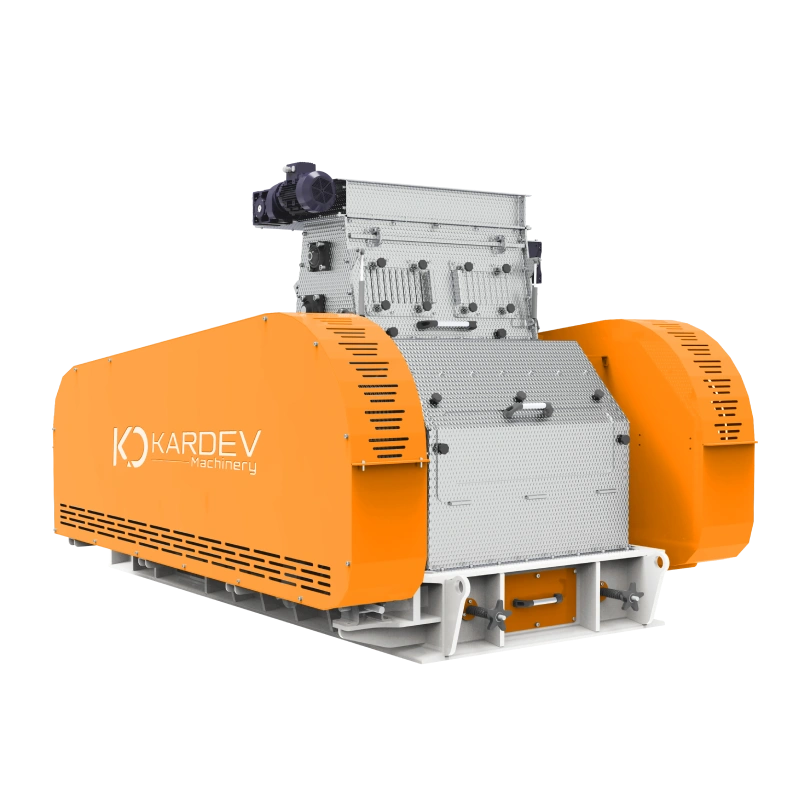

Vibrating Sieve

With sieves of different sizes, the vibrating sieve system separates materials according to their size and removes foreign objects. This ensures the materials are of the same granule size before processing.

Vibrating sieves are both durable and high-performance. Vibration motors help the sieve to separate the materials accurately.

The impact intensity of electric vibration motors can be adjusted according to the process. For example, even a vibration motor with a high newton value can be adjusted to supply just a small vibration force.The materials pass through gradually narrowing pores in multi-level sieves.

The sieves are easily removed or installed by opening and tightening the bolt connection. Vibration motors are mounted on the back of the machine in order to minimize space use.

Vibrating sieves are used for:

- Pre-sieving the material before being sent to the mill

- Sieving the material that comes out of the pellet mill

Advantages:

- Fast sieving

- Strong steel chassis

- Easy sieve change

- Minimum time loss

- Easy maintenance and use

- Low maintenance costs