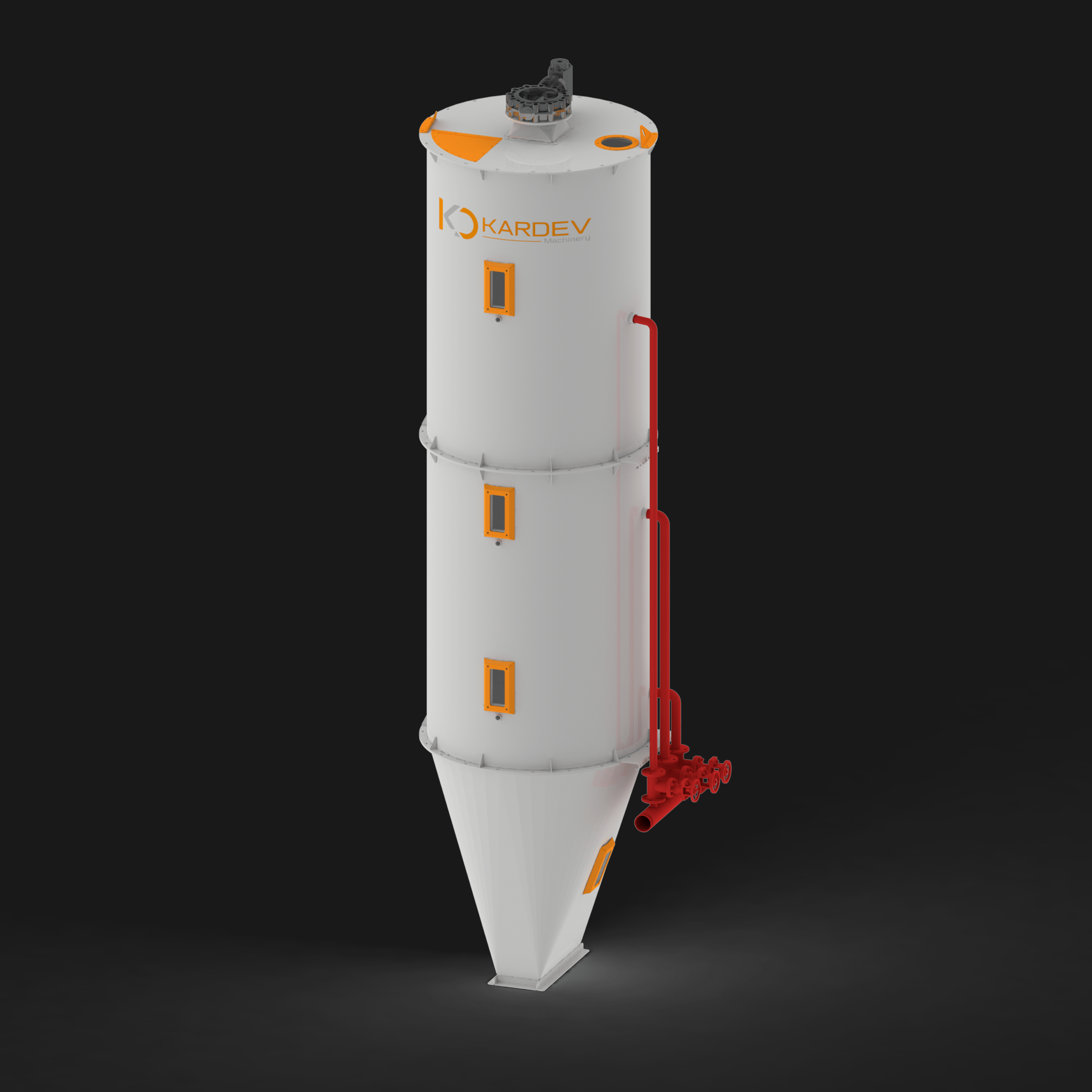

Steam Tower

Materials to be flaked are fed to the steam section which is located at the upper side of the chamber through the feeding hopper. A special steam distribution system directs the saturated steam to the product through several spots and distribute it evenly. The steam to be supplied to the raw material is controlled with the help of the solenoid steam valves located after the steam collector. The amount of steam to be given in the steam chamber varies according to the type of grain.

Thanks to the level sensors on the steam chamber, the on-off valves in the steam installation are controlled according to the grain amount and fullness in the tower.

The steam chamber, which is regularly steamed, is completely made of stainless steel. After manufacturing, the heat is maintained and the condensation of the steam is prevented by making insulation on the steam chamber.

KARDEV steam chambers are manufactured at intervals of 5-25 m3 according to different volume capacities. Tower volumes are determined according to the capacity of the flake unit.